Smart Manufacturing at Human Speed

Smart Manufacturing promised to transform the shop floor, but for many, the results have been uneven. Technology evolves in 18-month cycles, while people and processes move more deliberately. The next era isn’t about speed; it’s about alignment.

For years, Smart Manufacturing has promised to transform the shop floor. The vision was bold: connected sensors that predict downtime, AI-driven planning systems that balance workloads in real time, and data dashboards that make complex operations suddenly simple.

And while those tools have advanced dramatically, the results for most small and mid-sized manufacturers have been mixed. Many find themselves more connected than ever, yet not necessarily more productive.

The problem isn’t capability. It’s pace.

The Technology Curve vs. the Human Curve

Software and automation platforms evolve every 12 to 18 months. Machines might last decades, but digital systems don’t. By the time a company finishes integrating a new production dashboard or data platform, there’s often a newer, shinier version already being marketed.

Meanwhile, your team is trying to keep production flowing, not overhaul every process every year. Humans learn, adapt, and optimize at a very different pace than technology evolves. When you push one curve faster than the other, friction shows up; missed deadlines, unclear ownership, slow validation, and a backlog of “good ideas” that never make it past the prototype phase.

Why So Many Digital Transformations Stall

The most common trap we see is technology-first implementation. A company invests in an automation cell, cloud-based design suite, or IoT data layer, but the foundational processes that support planning, verification, and validation aren’t ready to absorb that change.

Instead of accelerating outcomes, new tools can actually slow the team down. Engineers spend more time learning software than improving product performance. Operators get more dashboards but less clarity. Management sees more data but not better decisions.

What Works Instead: Aligned Agility

At Perception Engineering, we’ve learned that the most successful companies approach Smart Manufacturing differently. They don’t start with the technology; they start with alignment.

Alignment means defining the fundamentals first:

-

Clear project briefs and goals

-

RACI responsibility structures

-

Risk assessments and mitigation plans

-

Consistent sprint cadences and retrospectives

It’s the same structured flow we use internally on every engagement:

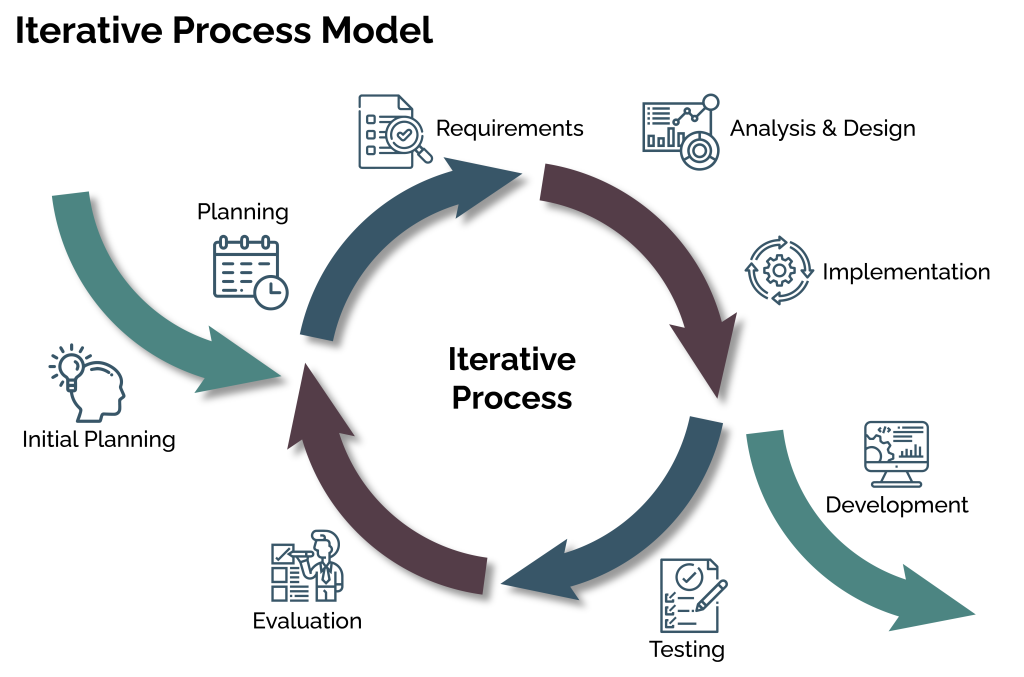

Planning → Verification → Execution → Validation → Approval → Learn.

When these human systems are in place, adopting new technology doesn’t disrupt the team; it amplifies it. You can add sensors, automate processes, or digitize documentation without derailing the workflow. The result is agility with intent, not reaction.

The Human Side of “Smart”

Smart Manufacturing isn’t just about code, sensors, and cloud dashboards. It’s about how people interpret and act on information.

A machine can measure torque variation to six decimal places—but it takes an experienced engineer to know when that variation actually matters.

That’s why we say Smart Manufacturing must happen at human speed. Technology should enhance human judgment, not attempt to replace it. The real gains come when experienced people have the clarity and tools they need to make better, faster decisions.

That’s the intersection we focus on at Perception Engineering: aligning people, process, and technology so teams can respond quickly and confidently.

The Bottom Line

The smartest factories of the next decade won’t be the ones that automate the fastest. They’ll be the ones that integrate the smartest; aligning their people, systems, and workflows so that every improvement actually sticks.

If your team is evaluating automation, design, or data initiatives for 2026, we’d love to help you make sure those investments fit your real-world processes, not the other way around.

📩 Let’s Talk Alignment

Schedule a quick discovery call with our team → Let's Talk!