Why Engineering Progress Is Rarely Linear in Production Systems

Engineering frameworks often assume linearity: requirements are defined, solutions are designed, performance is validated, and production follows. This model works well in controlled or greenfield environments. It becomes fragile when applied to operating production systems.

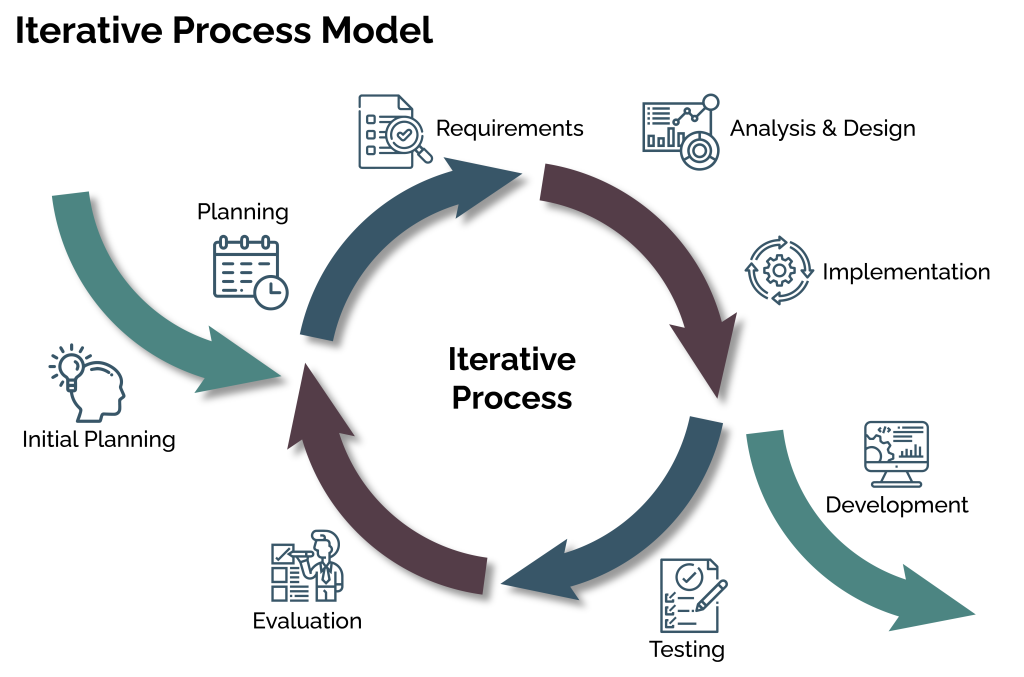

In high-mix, low-volume manufacturing, engineering work is continuously exposed to variability. Demand shifts, legacy constraints, undocumented process behavior, supplier inconsistency, and evolving customer expectations all introduce feedback after work has already begun. As a result, engineering progress tends to follow iterative loops rather than straight lines.

These loops are not inefficient by default. They are a function of information being revealed over time.

Problems emerge when organizations attempt to force linear execution onto systems that cannot support it. Common symptoms include late-stage design changes, excessive engineering change orders, and repeated validation failures that trace back to assumptions made too early. In many cases, teams are not revisiting decisions because new data has emerged; they are reacting because feedback was delayed.

Technically mature teams treat iteration as a controlled mechanism rather than a failure mode. Early prototypes are used to surface integration risks. Interface definitions are revisited as upstream and downstream constraints become clearer. Validation occurs incrementally, not as a single gate at the end of the process.

From a systems perspective, non-linear progress is often a sign that learning is occurring earlier in the lifecycle. While this can appear disorganized in traditional project tracking tools, it typically reduces total rework and stabilizes performance sooner once designs are released to production.

Engineering progress does not require predictability at every step. It requires decision points that are informed by real system behavior—and the discipline to adjust course when that behavior contradicts expectations.